Why Computerised Maintenance Management System (CMMS) is Essential for Efficient Manufacturing Operations

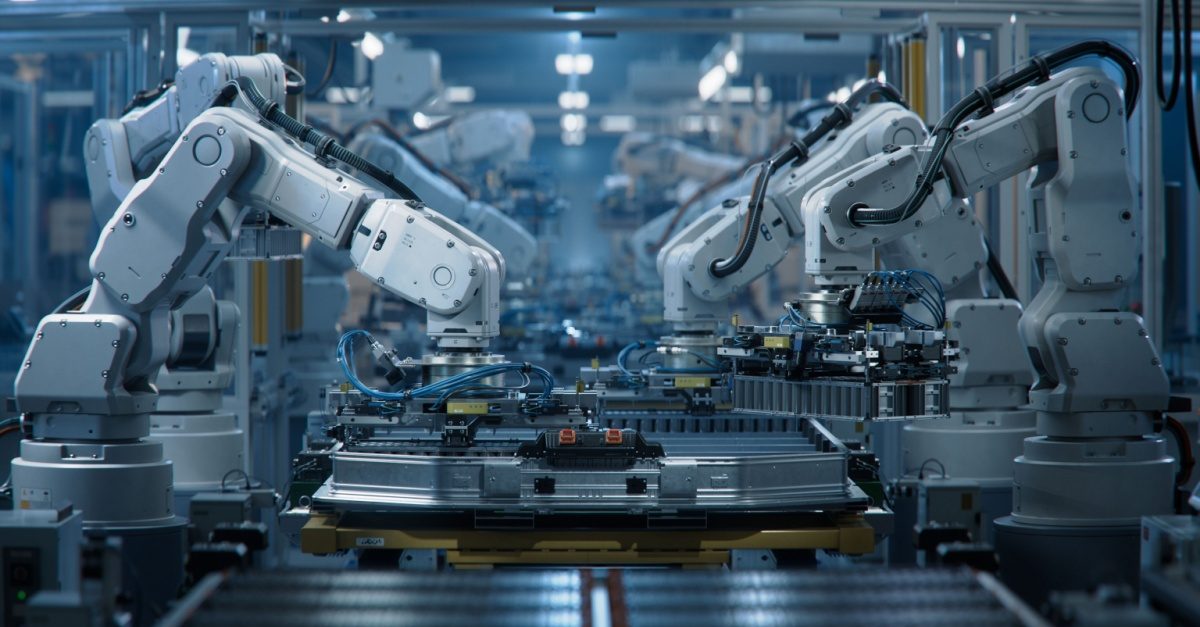

In today’s competitive manufacturing operations, operational efficiency is not just about producing more products, but it’s about producing smarter by leveraging full capacity. As modern factories adopt digital tools to streamline operational processes and increase efficiency, Asset availability is becoming increasingly critical for better productivity. Computerised Maintenance Management System (CMMS) helps to execute asset maintenance operations seamlessly to lower downtime. The Cloud providers simplify it by lowering the investment to adopt this advanced tool.

This article explores how these maintenance management systems supports efficient manufacturing operations by enhancing maintenance management, improving asset reliability, and delivering data-driven decision-making, all while keeping things practical and grounded in real-world needs.

What is CMMS Software in Manufacturing?

A CMMS is a software tool designed to manage, track, and optimise maintenance operations in an organisation. It serves as a central hub for all maintenance operations, including work orders, asset histories, preventive schedules, spare parts inventory, and more.

Unlike whiteboard methods or spreadsheets, CMMS platforms offer maintenance automation, operational visibility, and system operating procedures for consistency, essential elements for modern manufacturing.

Why Maintenance Management Matters in Manufacturing

Asset maintenance is often treated as a behind-the-scenes function, but its impact on manufacturing performance is anything but significant. Poor maintenance management can lead to frequent breakdowns, unplanned downtime, unsafe working conditions, and spiralling costs.

In contrast, well-structured systematic maintenance operations ensure that machines run reliably, production targets are met, and safety standards are upheld. It also enables predictive thinking to address potential issues before they disrupt operations.

Key Benefits of CMMS Software in Modern Manufacturing

Let’s break down the core CMMS benefits that make it essential for efficient manufacturing environments:

1. Minimising Downtime

Downtime is one of the biggest threats to productivity in manufacturing. When a critical piece of equipment fails, production halts, deadlines slip, and costs rise.

A CMMS helps prevent unplanned downtime by enabling proactive maintenance. With automated scheduling, alerts, and predictive maintenance features, teams can address wear and tear before it leads to failure.

2. Streamlining Work Order Management

In a busy plant, maintenance requests can quickly become chaotic. A CMMS brings structure by digitising work orders — from creation and assignment to tracking and closure. Maintenance teams always know what needs to be done, who is responsible, and when it’s due.

This streamlining reduces confusion, ensures accountability, and improves the speed and quality of maintenance work.

3. Extending Asset Life

Machinery and equipment represent a major investment. Keeping them in good health directly affects the bottom line.

With CMMS, manufacturers can monitor asset conditions, track service history, and analyse trends. This enables smarter maintenance strategies that prolong asset lifespan and delay the need for costly replacements.

4. Inventory and Spare Parts Control

One common challenge is discovering a needed spare part is missing during a breakdown. CMMS systems often include inventory tracking features that keep tabs on parts usage, availability, and reorder levels. This ensures that critical components are always on hand — without overstocking or unnecessary spending.

5. Data-Driven Maintenance Decisions

Data is the backbone of efficient operations. A CMMS collects maintenance data over time, creating a valuable source of insight. With built-in reporting and analytics, plant managers can identify recurring issues, evaluate technician performance, optimise maintenance schedules, and support long-term planning. These data-driven decisions contribute directly to improved efficiency and cost control.

According to a recent market report by MarketGrowth Reports, 78% of CMMS users reported at least a 15% improvement in operational efficiency. This underscores the measurable benefits that manufacturers can realise when shifting from reactive to data-driven maintenance strategies.

Supporting a Shift from Reactive to Preventive Maintenance

Many manufacturing sites still operate reactively — responding to failures as they happen. While this may seem manageable in the short term, it usually leads to more expensive repairs, safety risks, and unplanned downtime.

One of the key benefits of CMMS in manufacturing operations is enabling a shift to preventive maintenance. With scheduled servicing and condition monitoring in place, equipment is maintained before problems escalate. This cultural shift can dramatically increase overall equipment effectiveness (OEE) and reduce operating costs.

Some advanced CMMS platforms even support predictive maintenance, using IoT sensors and real-time data to detect anomalies and predict failures in advance.

Compliance and Safety Improvements

In highly regulated manufacturing sectors — such as food, pharmaceuticals, or automotive — compliance with maintenance standards is critical. A CMMS helps ensure that inspections, calibrations, and servicing are performed on time and properly documented. This not only improves product quality and plant safety but also simplifies audits and reduces the risk of regulatory penalties.

CMMS for lean manufacturing

Many manufacturers adopt lean principles to eliminate waste and optimise resources. A CMMS aligns well with this philosophy by supporting lean maintenance practices:

- Reducing unnecessary maintenance work

- Minimising spare parts stockpiles

- Shortening machine downtime

- Improving maintenance planning efficiency

CMMS software plays a critical role in lean manufacturing by enabling smart, efficient maintenance tracking and planning

Making Maintenance a Team Effort

Another overlooked benefit of CMMS is improving communication across departments. Production teams can easily log issues, maintenance technicians can see task priorities, and managers have a clear overview of maintenance activities.

Everyone stays on the same page, reducing delays, miscommunications, and duplicated effort. In short, it helps break down silos and fosters a more collaborative maintenance culture.

Barriers to Adoption — and How to Overcome Them

Despite the clear benefits, some manufacturers hesitate to adopt CMMS tools due to cost, complexity, or resistance to change. These are valid concerns, but they can be addressed:

- Start small: Begin with a basic CMMS setup focused on high-priority equipment.

- Train teams: Offer training and support to help staff use the system effectively.

- Show value: Use early wins (e.g. reduced downtime or improved response time) to demonstrate the system’s impact.

With the right approach, CMMS adoption becomes a strategic investment rather than a daunting project.

Examples of CMMS Platforms in the Market

For organisations evaluating options, here are a few notable platforms to consider:

- Fogwing CMMS – A maintenance software that integrates AI and IoT capabilities for maintenance tracking and inventory control

- Limble CMMS – User-friendly design with strong mobile access and custom workflows.

- Fiix – Offers open APIs and predictive capabilities for asset-intensive industries.

- UpKeep – A mobile-first CMMS ideal for small and mid-sized teams.

Each of these platforms has different strengths. The best fit depends on factors such as company size, asset complexity, industry requirements, and total cost of ownership.

Final Thoughts

In an age where manufacturers are under constant pressure to produce more, waste less, and maintain high standards, CMMS has emerged as a critical enabler of efficiency and reliability.

By improving maintenance management, extending asset life, and enabling informed decision-making, a CMMS transforms maintenance from a reactive burden into a strategic advantage.

For manufacturers aiming to stay competitive, sustainable, and future-ready, embracing a CMMS is no longer optional — it’s essential.

Completing a manufacturing and production course with the Institute of Supply Chain Management (IoSCM) certifies your knowledge and skills to give you the best grounding for progression in your career. With our expert support network and unmatched resources, we provide more than just a manufacturing qualification – we give you the tools to grow, learn and progress as an industry professional.