Summer heat for some means spontaneous family trips, poolside fun, and relaxing beaches. However, it’s a different story for those in manufacturing. Summer heat equates to occupational hazards. Not only does the season’s soaring temperatures cause issues, but heat-producing machinery along with lengthy work hours can make it downright exhausting for laborers.

Sometimes referred to as “hot work”, soaring temperatures in the warehouse and factory floor can create a dangerous environment for workers. Plus, adding vigorous tasks that involve open flames, electrical friction, heated gasses, and hot surfaces/materials can further threaten their safety. Too much exposure to these dangers can cause heat stress, burns, and injuries.

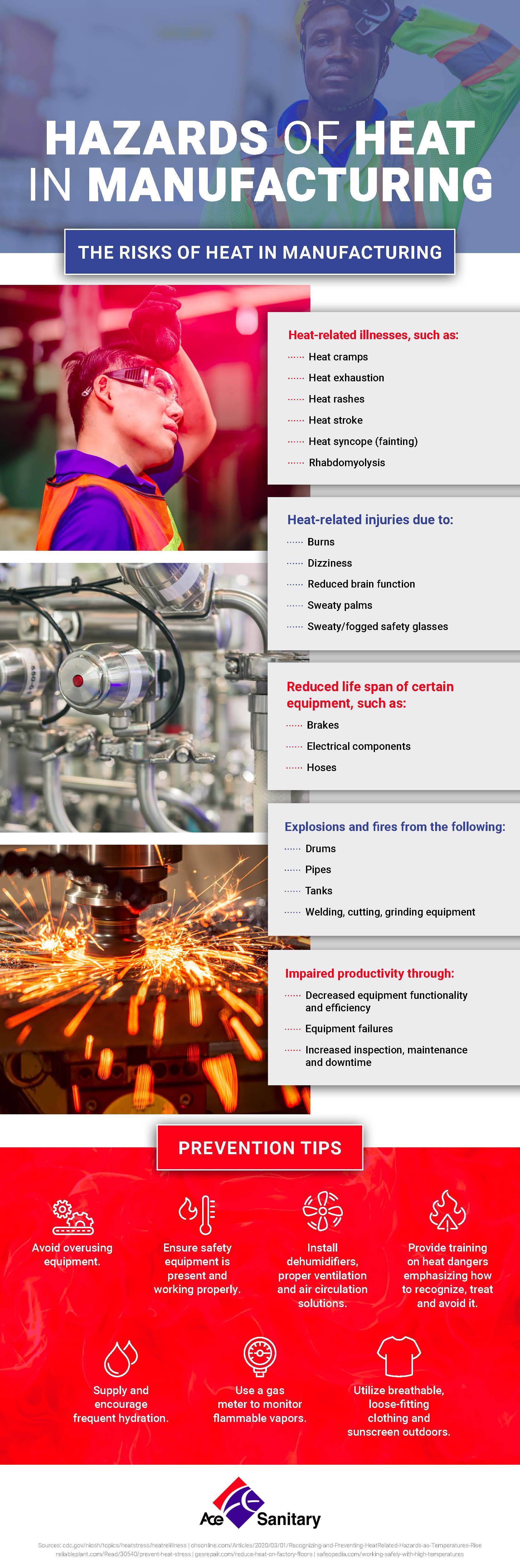

Risk To Employees

Unresolved heat stress can cause many harmful health effects such as heat stroke/exhaustion, cramps, rashes, serious illnesses and in some cases, death. Between 1992 and 2017, over 815 laborers were killed while 70,000 were critically injured from heat stress. Worker that are either 65 or older, take medication, are overweight, have heart disease or suffer from high blood pressure are at even greater risk than others.

Risk To Equipment

When introduced to dangerously high temperatures, factory equipment can begin to malfunction. There is heavy-duty machinery that is designed to resist heat, but some parts are still at risk of failing or deteriorating over a period of time. Essential pieces such as sensors, hosing, and electrical components could also have a decreased life span from regular exposure to extreme temperatures.

Beating The Heat

Despite the hefty consequences, there is hope in minimizing the threat of heat exposure. Firstly, the importance of installing and maintaining a functioning ventilation and cooling system cannot be understated. However, only consider it if it’s applicable to the situation.

Encourage employees to stay hydrated throughout the workday. Having just mild dehydration—which is typically asymptomatic—can negatively influence their reaction time and productivity. Implement training programs that educate workers about the risk of heat stress and dehydration along with warning signs and treatment.

Additionally, it’s important for factory equipment not to overheat or become overused. Create an extensive monitoring system to replace or repair any broken equipment to prevent failures and possible injuries to employees.

Protecting your workers from heat-related dangers doesn’t stop there. As a business, you can further safety measures for the benefit of your establishment.

Check out the accompanying graphic created by Ace Sanitary for more information on how you can help your employees and equipment.