How Industrial Lighting Increases Safety And Productivity In Manufacturing Facilities

“The difference between something good and something great is attention to detail.” – Charles R. Swindoll

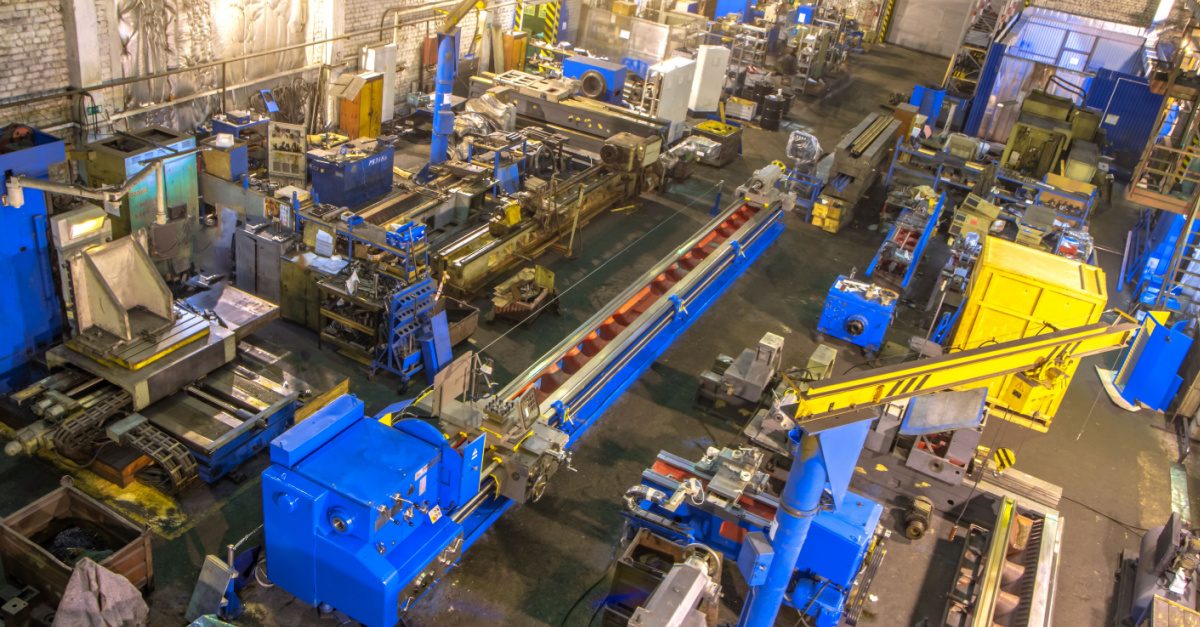

What if we told you that there’s a simple yet highly effective way to enhance safety and productivity in your manufacturing facility? What if it’s not just about upgrading your machinery or improving workflow processes? The truth is, something as seemingly insignificant as your facility’s lighting can have a profound impact on the safety and productivity of your employees. In this article, we will explore the power of industrial lighting and how it can transform your facility into a safer and more efficient workspace.

The Importance of Proper Industrial Lighting

Manufacturing facilities are the backbone of the American economy, and ensuring the safety and productivity of these workspaces is paramount. With the right industrial lighting fixtures, you can greatly improve visibility, reduce accidents, and increase overall productivity.

Safety First

Proper illumination is a vital component in creating a safe working environment. Poor lighting can lead to accidents, injuries, and even fatalities. In fact, the Occupational Safety and Health Administration (OSHA) has set forth specific guidelines for adequate lighting in industrial settings. By meeting or exceeding these standards, you can minimise the risk of accidents and promote a culture of safety within your facility.

Boosting Productivity

Alongside safety, the right lighting can also enhance productivity. Adequate lighting levels have been shown to reduce eye strain and fatigue, allowing employees to work more efficiently and accurately. Furthermore, well-lit workspaces can boost employee morale, leading to increased motivation and job satisfaction.

Quick Tips to Improve Industrial Lighting

- Upgrade to LED Lighting: LED lights are energy-efficient, have a longer lifespan, and provide a higher quality of light compared to traditional lighting sources.

- Optimise Light Distribution: Ensure that light is evenly distributed throughout the facility to prevent dark spots and glare.

- Choose the Right Color Temperature: Cooler color temperatures (5000K-6500K) are ideal for industrial settings, as they promote alertness and productivity.

- Implement Task Lighting: Provide additional lighting in areas where specific tasks are performed to improve visibility and reduce eye strain.

- Consider Natural Light: Whenever possible, utilise natural light through windows and skylights to improve overall lighting conditions.

Lighting Design Principles for Manufacturing Facilities

1. Visual Comfort

Visual comfort is a crucial factor in creating a productive work environment. By minimising glare and providing consistent illumination, you can ensure that employees can comfortably perform their tasks without experiencing eye strain or discomfort.

Key Considerations:

- Choose fixtures with proper glare control.

- Use indirect lighting or diffusers to distribute light evenly.

2. Adaptability and Flexibility

Manufacturing facilities often undergo changes, such as reconfiguring layouts or introducing new equipment. Your lighting system should be adaptable and flexible enough to accommodate these changes without compromising safety or productivity.

Key Considerations:

- Opt for modular lighting systems that can be easily reconfigured.

- Consider adjustable and mobile light fixtures that can be moved as needed.

3. Energy Efficiency and Sustainability

Energy-efficient lighting solutions not only reduce operational costs but also contribute to a more sustainable future. By incorporating energy-efficient technologies and design strategies, you can create an eco-friendly lighting system that benefits both your facility and the environment.

Key Considerations:

- Upgrade to LED lighting.

- Implement lighting controls, such as occupancy sensors and timers.

- Utilise natural light through windows and skylights.

4. Compliance with Standards and Regulations

Meeting or exceeding industry standards and regulations, such as OSHA guidelines, is vital for ensuring the safety and well-being of your employees. Familiarise yourself with the relevant guidelines and ensure your facility’s lighting system complies with these requirements.

Key Considerations:

- Consult OSHA guidelines for recommended lighting levels.

- Ensure your lighting system meets local and national electrical codes.

5. Maintenance and Durability

A well-designed lighting system should require minimal maintenance and feature durable components to withstand the rigors of an industrial environment. Investing in high-quality lighting solutions can save you time and money in the long run.

Key Considerations:

- Choose lighting fixtures and components with a proven track record of durability.

- Opt for LED lights, which have longer lifespans and require less frequent maintenance than traditional lighting sources.

By incorporating these design principles into your industrial lighting strategy, you can create a safe, productive, and efficient work environment that supports the success of your facility and employees.

FAQ: Common Questions About Industrial Lighting

Q: How do I know if my facility has adequate lighting?

A: To determine if your facility has adequate lighting, you can perform a lighting audit. This involves measuring light levels, assessing light distribution, and evaluating the overall quality of light in your facility. You can also consult with a lighting professional for guidance.

Q: What are the OSHA guidelines for industrial lighting?

A: OSHA recommends different lighting levels depending on the specific task being performed. For example, general manufacturing areas should have a minimum of 30 foot-candles (fc) of illumination, while detailed inspection tasks may require up to 100 fc. It’s essential to consult OSHA’s guidelines and ensure your facility meets these standards.

Q: How can I reduce energy consumption in my facility’s lighting system?

A: Upgrading to energy-efficient LED lighting, utilising natural light, and implementing lighting controls (such as occupancy sensors and timers) can significantly reduce energy consumption in your facility.

Q: Can better lighting really improve employee productivity?

A: Yes, studies have shown that proper lighting can have a positive impact on employee productivity. Improved visibility reduces eye strain and fatigue, allowing employees to work more efficiently. Additionally, well-lit workspaces can boost morale, leading to increased motivation and job satisfaction.

Conclusion: Unlocking the Potential of Industrial Lighting

In conclusion, proper industrial lighting is an essential component of a safe and productive manufacturing facility. By upgrading to LED lights, optimising light distribution, choosing the right colour temperature, implementing task lighting, and making the most of natural light, you can create a working environment that promotes both safety and productivity.

As a facility owner or manager, you have the power to make a meaningful impact on your employees’ well-being and your facility’s overall success. Don’t underestimate the potential of industrial lighting—invest in the right industrial lighting fixtures and watch your facility thrive.

By embracing the power of industrial lighting, you’re taking a critical step towards ensuring the adaptability and success of your manufacturing facility. Light the way to a brighter future for your employees, your facility, and the economy.

Unlock the potential of your manufacturing team with professional training and development. IoSCM can support you with meeting your strategic objectives quickly and easily. Call 0800 1422 522 today.